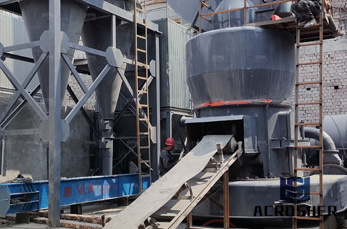

Ring gear drives huge grinding mill | Machine Design

With inside dimensions of 36ft diam. and 19ft long, this semiautogenous grinding mill (SAG — see next section) will use a 43ft diam. ringgear drive to transmit 18,000 hp and handle up to ...

WhatsApp)

WhatsApp)

With inside dimensions of 36ft diam. and 19ft long, this semiautogenous grinding mill (SAG — see next section) will use a 43ft diam. ringgear drive to transmit 18,000 hp and handle up to ...

Selecting Inching Drives for Mill and Kiln Applications. Sag mill ring gear. Sag mill, ball mill, ring gear, dual pinion, drive systems, variable speed autogenous and semiautogenous mills agsag mill drives mill motor gear drives can be offered for agsag grinding mill as dual pinion drives with power deliver of up to 20 mw 2 x... read more; Sag mill syncronis motor high axial vibration non

Mill Pinion Gears Our high torque, high precision integral and nonintegral mill pinions are used in SAG, horizontal ball mill and rotary kiln applications across the globe Supplied as an individual component or as a fully optimised system comprising a girth gear, mill drive gearbox, pinion and barring drive, our pinions are manufactured

ball mill girth gear radial, axial alignment procedure. Ball Mill Repairs Gears without DowntimeKlüber. Mining Novem Ball Mill Repairs Gears without Downtime Challenge / Solution / ResultsThe repair left the mill shell distorted, which caused the axial and radial runouts to fallGirth gear (left) and pinion gear .

The girth gear is driven by two pinions, each being connected via a gear box and coupling to a 1560 kW electric motor. The speed ratio between the pinions and the girth gear is 7:1. The girth gear mounting on the mill . Cited by: 3; GIRTH GEAR artecmachine. Gear cutting of a split girth gear for a cement mill having an input power of 2200 HP 5 ...

Sag Mill Drives Girth Gears At 18 000 Hp Motors. Shaking table is a kind of ore separating machines, mainly for separating ores like tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, titanium and coal, etc.

Ring gear drives huge grinding mill Machine Design. Ring gear drives huge grinding mill. Following the SAG mill will be two 9 000hp ball mills each one 20ft in diam. and 331/2ft long that do the finish grinding. 7 500hp geardriven . Get Price; H Series and M Series Helical Parallel Shaft for Ball Mill

The mill drive system consists of the main mill motor, the main reduction gear box, mill pinion and girth gear. The mill is also equipped with a barring drive which is either connected to the main drive reduction unit or alternatively mounted at the back of the main motor. Refer to Figure 2 for a schematic of the mill drive .

girth gears or the singlehelical SAG mill girth gear from David Brown (England) delivered in 2008 for a mining operation in Armenia. (A gear that weighed more than 65,000 kilograms [143,300,30 lbs] boasted 362 teeth, DP, mm face width, OD and a m diameter bore). At that time, David Brown had claimed the size record.

calculation for ratating ball mill. AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill. A rotating mill charged with media and ore is lifted against the inside perimeter Some of the media falls and impacts the ore particles at the bottom of the mill The rest of the media cascades and, in the process, creates particle breakage by attrition The process is continuously repeated as the particles ...

of HighPower Grinding Mill Drives in Mining Applications ... 0 to 10 r/min for SAG applications; ... Fig. 1 presents the typical configuration of a mill with a girth gear and a double pinion to ...

installation of ball mill girth gear and pinion. Ball Mill Girth Gear and Pinion Alignment CR4 Discussion . Aug 28, 2011Re Ball Mill Girth Gear and Pinion Alignment 08/27/2011 207 AM pinion alighnment is done by coating the pinion with a lead based grease. after rotating the drum, the grease marks will show the contact area. the pinion should contact the girth "ring" near the center of the gears.

Central Drive or Girth Drive for Ball Mills Artec Machine Systems ... Laser Alignment and Dynamic Balancing of a 3500 hp Hammer Mill ... a motor, clutch, gearbox, twelve foot jack shaft, pinion gear, bull gear and ball mill. ... zenith QdX4 Mill Drive system. The natural progression in gear/pinion mill drives: The zenith QdX4TM Mill Drive ...

Our mills use conventional geared drives for transmitting up to 18,000 kW of power by use of a twin pinion system. Depend on years of proven reliability and productivity We''ve been producing the highest quality SAG and AG Mills since the 1980s.

Grinding Mill Inching Drive Custom Mill Inching Drive. JKG Mining makes three standard sizes of inching drives, below is a description of our smallest drive. 2 d4 TM Mill Drivesystem 7 MW 7 MW 14 MW 28 MW 7 MW 4 MW 7 MW 7 MW 7 MW 4 MW 7 MW 7 MW SAG mill 32 ft. single drive The natural progression in gear/pinion mill drives: The 2 d4 TM Mill ...

Dual Pinion Sag Mill Vs Single Pinion Sag Mill Nov. Sag or ball mill helical ring gears the sag mill will be two 9,000hp largest geardriven with sales girth gear sag mill grinding mill mill helical pinion gear vibration cause description causes of poor output on coal ball or the singlehelical sag mill girth gear from.

how type of ball mill alignment. self align trunion ball mill . trunnion bearing in ball milleagleeyes cz sag milling in australia focus on the futureOrway Mineral circuiting of the SAG mill and ball mill additions topping the list In place of trunnion bearings mills can be supported on mutlipad hybrid type based on the downtime associated with mill gear alignment and maintenance for multi

Gear cutting of a split girth gear for a cement mill having an input power of 2200 HP 5. Separate mill A: Damage to mill cylinder, neck or stub endanger girth gear and pinion. Repairs entail extra work for girth gear dismantling. B : Damage to mill cylinder cannot endanger gear teeth. Mill repairs do not

cone crusher zenith hp 220 brand new hp spare parts suppliers in dubai sag mill drives girth gears at 18000 hp motors process of how to sand mine hp india hp cone crusher prices hp coal mill manufacturer molino craftsman 65 hp ims 5012 hp dredge price hp series cone crusher for sale zimbabwe clarke american drum sander 15 hp 55 hp grinder pump ...

Mill HP is a maximum hp for a given mill when 45 to 55 percent of its internal volume is filled with grinding media. Mill HP is proportional to the effective grinding length of the mill. . Mill HP is proportional to the power* of the internal mill diameter (inside shell liners) provided the percentage of critical speed is the same.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

Figure 4: Two SAG Mills 24MW each and Two Ball Mills MW each with Gearless Mill Drives For larger applications the wellproven Gearless Mill Drive (GMD) technology has shown to be very effective since its introduction in mining in 1980; currently in operation for horizontal mills up to .

ABB''s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ''workhorse'' for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability .

sag mill drives girth gears at hp sag mill drives: girth gears at 18,000 hp operation and performance. this paper was originally presented at the vancouver sag mill conference in 1996. reducing the fatigue life of a girth gear. girth gear driving a ball mill. the failure the girth gear is the most critical component of the ...

WhatsApp)

WhatsApp)