Gold Extraction by Chlorination Process YouTube

Aug 23, 2014· Modern technology has improved the process of using chlorine as a method to dissolve gold. Resin technologies have virtually eliminated the early problems associated with using chlorine .

WhatsApp)

WhatsApp)

Aug 23, 2014· Modern technology has improved the process of using chlorine as a method to dissolve gold. Resin technologies have virtually eliminated the early problems associated with using chlorine .

Aqua Regia gold refining and sedimentation machine. ... This indicates that the Aqua Regia solution also has nitric oxide, in addition to nitrosyl chloride and chlorine. Step three: The gold alloy is put into the Aqua Regia solution, and this causes only the gold to dissolve in the solution. The chemical equation for this step is shown below:

Gold Refining using Aqua Regia, Dislolve gold Gold River Refining. Dissolving Gold in an Aqua Regia Solution is a Gold Refining Process Gold . and Gold Ores, have other elements and precious metals mixed with them. . and get the gold into its pure form, a separation process or gold refining process needs . A Chlorine atom has 7 electrons in ...

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

chlorination gold recovery. Recovery of Gold from Incinerated Sewage Sludge Ash . In a series of studies into the development of an efficient and selective recovery process for gold that eliminates the need for water, the release behavior of gold from an incinerated sewage sludge ash heated to between 100 and 1000 C under a chlorine gas stream was investigated.

gold refining machine chlorination formula. gold refining machine chlorination system lemedievalbe. The Prioksky NonFerrous Metals Plant has its headquarters and large gold refinery in the Prioksky District, near the city of Kasimov in the Ryazan region Gold refining methods include pyrometallurgical chlorination, wet chemical System ...

Aqua regia is primarily used to produce chloroauric acid, the electrolyte in the Wohlwill process for refining the highest quality (%) gold. Aqua regia is also used in etching and in specific analytic procedures. It is also used in some laboratories to clean glassware of .

Apr 24, 2017· How to Use Bleach on Gold Ore to Remove Gold ... When combined with hydrochloric acid, the mixture produces chlorine that dissolves gold from gold ore. This was the first commercial method used for gold extraction. Place the ore into the mortar and grind it to the size of sand grains. Put the ore grains into a plastic bowl.

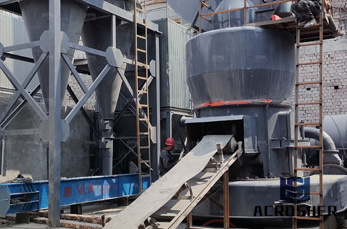

Gold Chlorination Refining Machine Sri Lanka, Gold processing mobile unit. Zenith gold chlorination refining machine shows high performance and efficiency in gold concentration ore processing is to beneficiate the raw materials to obtain its economic value.

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Gold Refining Systems, Inc., is an innovative Company devoted to helping gold miners, prospectors, jewelers and refiners of all sizes to refine gold, silver and other precious metals safely, efficiently, and with ease. Our Company is establishing higher standards in precious metal refining industry for safety, pollution control and efficiency.

Stephen Foley is looking to get his hands on some gold. the problem is that it takes too much time, costs too much money and harms the environment. The work of his research team—made up of ...

Reverse electroplating for environmentfriendly gold recovery / refining 2001. Q. I am about to embark on scrap circuit board recycling, primarily for the gold and platinum content. I am about to set myself up with an acid solution [aqua regia], that dissolves the .

Gold Refining Equipment and Systems for Electrolytic, Aqua Regia Purification of Gold, Silver Platinum, The chlorine gas, Check price. gold crushing machine chlorination blueoceanconstruction. formula for down hours Jaw crusher is the most used gold mining machine for crushing ore. concentration gold in ore Gold Refining Machine .

Chloride–hypochlorite oxidation and leaching of refractory sulfide gold concentrate 63 Fig. 1. The Pourbaix diagram of Fe–S at [Fe] –= 10 4 M, [S] = 10– M and 25 C (the chlorine species regions are also marked) (Marsden and House, 2005) Fig. 2.

Refining – Gold and Silver Metallurgy. Process Plant Design. Prospecting and Exploration. . The Miller chlorination process is well know and has been practiced for a long time in the gold refining industry.. Click Chat Now

Page 1 of 2 Gold Refining posted in Chemistry: I was looking into gold refining and came across a lot of information on Aqua Regina. While I found quite a feww stepbystep articles, I have yet to find anything that explaines exactly why mixing these acids can dissove gold. Anyone care to lent this old phogy some help in the matter?

Aqua regia (often abbreviated as AR) is a mixture of hydrochloric acid and nitric acid capable of dissolving many noble metals like gold, platinum and are a number of metals that resists aqua regia, they are titanium, iridium, ruthenium, tantalum, niobium, hafnium, osmium, rhodium and alloys with high amounts of silver is also resistant to aqua regia as there ...

Gold Recovery Correctly: I will detail a SAFE process of turning old electronic parts into little round lumps of pure gold. There are many tutorials that claim to offer methods of gold recovery such as "Cupellation"*. These processes are DANGEROUS and put the user at t...

*Cupellation is a refining process in metallurgy, where ores or alloyed metals are treated under high temperatures and controlled operations to separate noble metals, like gold and silver, from base metals like lead, copper, zinc, arsenic, antimony or bismuth, present in the ore.

May 23, 2015· Instructions Weigh your gold smelt. For every ounce of gold, you will need a container with a 300milliliter capacity. So, if you''re refining 5 ounces of gold, you will need a 1500milliliter container or about 1 ½ quarts. Add 30 milliliters of nitric acid for every ounce of gold. So, if you''re refining 5 ounces of gol

salt water gold refining saluteindia. salt water based refining machine BINQ Mining. Salt is harvested through solar evaporation from seawater or salt lakes. 12 grams Actual gold was 1. salt water gold refining. A wide variety of water refining machine options are available to .

The procedure is very similar to refining gold in aqua regia, but the precipitant used will be different. There are several standard precipitants, different precipitants for different platinum group metals. Refining by this method is tricky and the purity of the resultant platinum group metal is often below normal standards.

Gold refining by solvent extraction—the Minataur™ Process by A. Feather*, Sole*, and Bryson* Synopsis The Minataur™ Process (Mintek Alternative Technology for Au Refining) is a novel route for the production of highpurity gold using solvent extraction. Following the successful

WhatsApp)

WhatsApp)