Conveyor Belt Market Research Report Till 2026 : Global ...

Conveyor Belt Market Report 2026 This report provides global market growth, trends, size, share, demand, forecast, company profiles and segmented by types, application and by region.

WhatsApp)

WhatsApp)

Conveyor Belt Market Report 2026 This report provides global market growth, trends, size, share, demand, forecast, company profiles and segmented by types, application and by region.

APPLICATIONS: These conveyor belts can carry objects with extreme temperatures straight out of furnaces or freezers. In addition, machines in the food industry, in particular, must survive running through glaze, breading, or hot oil. Because they can securely handle both wet and greasy items, larger washdown conveyors with flat wire belts are ...

Aug 10, 2019· To improve abrasion resistance, you can make adjustments to how the belt is operating. Or you can choose a more durable belt, a different type of belt fabric, or acquire a belt cover. Comparing Mining Conveyor Belts. Choosing the right mining conveyor belt for demanding applications depends on the careful comparison of the factors discussed here.

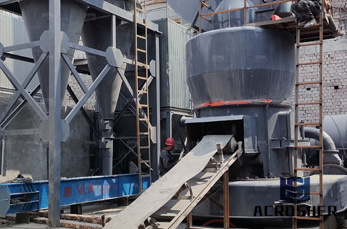

First from belt system to explain: Belt Conveyor is one of the most important material transporting and handling equipment, can be widely used in mining, metallurgy, building materials, chemical industry, electric power, food processing industries, coal mines, metals, iron and steel enterprises, ports, cement factories and other fields you can see.

Nov 06, 2019· Mining and quarrying belts: They are heavyduty belts used for applications in mines and quarries. They can transport materials such as ore, stone, tailings, gravel, aggregate, etc. ... The kind of fibre and the type of fabric weave used as the carcass material depends upon the requirement of the application. Conveyor belts are the boon in the ...

Jan 31, 2019· PVC Conveyor Belts. PVC conveyor belts, otherwise known as solid woven conveyor belts, are used in the mining industry to transport aggregates, materials, and fines from the openpit or underground mines to the mine plant or the stacker system. PVC is used in underground and aboveground applications .

Conveyor Applications and Industries. Conveyor selection depends on product type, throughput or speed, elevation change, and in some cases, industry focus. Belt conveyors, for instance, come in a variety of sizes and can range from footlong units used on packaging lines to milelong systems used for mining operations.

Range of application of R28 conveyor belt fasteners is considerably wide, joints can be applied to all types of belts used in mining. Joints as well as type of stitching have been developed mainly with a view to long strongly burdened conveyors.

Troughed belt conveyors are used prolifically throughout the mining industry, carrying ores, concentrates, and tailings throughout every stage of the mining cycle, from initial excavation, through beneficiation, to the production of a refined material ready for market, and each step in between.. Belt conveyors are customized and combined in an endless array of configurations, making each ...

Conveyor belts'' application in the Mining industry. The uneflex''s flexible coupling''s aim consists on transferring the torque from the motor side to the roller drives, so as to move the big metalcylinders that are fixed to the conveyor belt.

Belt Conveyors employed in mining applications . Belt conveyor systems continuously transport all forms of material, including excavated and crushed rock in an efficient manner over long distances, passing through curves and rough relief areas. Belt conveyor systems requiring anything up to 20,000 t/h capacity are anything but a rarity in mining.

The singlepulley drive is ideal for low horsepower conveyors. The head drive includes a pulley, motor, and gearbox, all mounted on the Aframe design. Skidmounted drive / takeup. The skidmounted drive / takeup is a single unit that provides the necessary power for your conveyor system, while maintaining proper belt .

Keywords: BPJ1, conveyor belt, explosionproof. The conveyor belt is important transportation equipment in the mining. Only keep the conveyor belt stable operation, ensure the safety and then it can transfer the coal to ground and produce profit. As we knew in the mining industry, explosion protection is the necessary.

Keywords: BPJ1, conveyor belt, explosionproof. The conveyor belt is important transportation equipment in the mining. Only keep the conveyor belt stable operation, ensure the safety and then it can transfer the coal to ground and produce profit. As we knew in the mining .

Conveyor belts are available with a wide range of accessory products for a wide range of applications. Common conveyor system accessories include conveyor belt fasteners, belt lacing strips, clipper lacing, hooks, plate grips, and installation tools. Proper Care. The first step in caring for your conveyor belt has to do with how you use it.

UKRB multiply conveyor belts are ideal for moving bulk materials in a diverse range of industries. Suitable for the bulk handling of heavyduty and abrasive materials in extreme conditions, they are used by the quarrying, mining.

Mining belt conveyor systems. Increasing efficiency and extending conveyor belt life cycle . Creating a drive system for multiple conveyor belts requires indepth know how. Our offering, based on our experience applying solutions on more than 600 kilometers of belt conveyors.

Mining samplers from Multotec include cross belt, wet and dry cross cut and combination sampling systems, guaranteeing extremely accurate ore samples.. As a worldleading supplier of mining samplers for dry and wet ore loads, we design and manufacture applicationspecific mining samplers that ensure all particle sizes are caught from across the ore stream, for maximum accuracy of your ore sample.

Conveyor belts for every mining application ContiTech is a multinational corporation with operations in almost all countries around the world. We provide a wide range of conveyor belts and related products, longtime experience, comprehensive technical and project management expertise and technical

Conveyor Belts The transport of large quantities of bulk material, especially in mining industry and mine areas, requires the continuous use of conveyor belts. Lacerations, damage to the fasteners, edge damage or just partial wear are a constant problem.

Belt conveyor systems requiring anything up to 20,000 t/h capacity are anything but a rarity in mining. TAKRAF''s knowhow and significant experience in this area is a critical success factors to projects of such scaled and magnitude.

Jul 12, 2019· Aside from application and conveyor environment, here''s a look at some other key factors that play a part in deciding on a conveyor belt. Fireproof If your mining conveyor is operating in an underground environment, then it likely has to comply with MSHA Part 14 fire resistance requirements.

Mining samplers from Multotec include cross belt, wet and dry cross cut and combination sampling systems, guaranteeing extremely accurate ore samples.. As a worldleading supplier of mining samplers for dry and wet ore loads, we design and manufacture applicationspecific mining .

Belt conveyors are used to mechanise material handling operations in foundries to distribute moulding sand, mouldcores and cast articles. Belt conveyors are used for carrying coal, ores and minerals in power plants, mining industries, metallurgical process plants. For handling food grains and building materials belt conveyors are frequently ...

WhatsApp)

WhatsApp)