In the Groove with Diamond Grooving and Grinding

Jul 02, 2014· Diamond grooving and grinding is a concrete pavement preservation technique that corrects a variety of surface imperfections on concrete pavements, and .

WhatsApp)

WhatsApp)

Jul 02, 2014· Diamond grooving and grinding is a concrete pavement preservation technique that corrects a variety of surface imperfections on concrete pavements, and .

Shop 5 Concrete Grinders at Northern Tool + Equipment. Browse a variety of top brands in Concrete Grinders such as Husqvarna and Norton from the product experts.

Slippery when wet. But it is becoming common to do something more than warn motorists. Sawing grooves into pavements greatly reduces wet weather skidding accidents on roads and airports. During the past 15 years more than 5 million square yards of highway pavements have been grooved and accident records verify that grooving creates safer highways.

Concrete diamond grinding removes roadway imperfections caused by construction and/or heavy usage. The immediate result is an improvement in pavement smoothness, surface texture, skid resistance, safety, and noise reduction.

Rent a Concrete Grinder 10" from your local Home Depot. Get more information about rental pricing, product details, photos and rental locations here. ... Concrete Tools Concrete Grinder 10" EDCO | category #09 group #980. Concrete Grinder 10" Description Model # 50200HD. Perfect for indoor surface grinding applications, including garage ...

Jan 17, 2019· Concrete grinding concrete leveling, floors, thinset removal, floor grinding, floor leveling, coating removal and resurfacing concrete in Phoenix Arizona. ... This is the most aggressive tool. For a journeyman concrete finisher this is a tool that can be perfected and can do beautiful work out of ugly concrete. This is the machine and wheel ...

HTC EZ M Series Floor Grinding Tools for medium concrete The new, improved M Series. Faster in the beginning and lasts longer in the long run! The M Series is a complete line of floor grinding tools for use on normal to soft concrete,...

Scarifiers, also called surface planers or milling machines, remove concrete faster and more aggressively than grinders. That''s because they use the pummeling action of multitipped cutting wheels, or flails, that rotate at high speeds to chip away at the concrete surface.

SASE Signature Floor System.. This system is designed for industrial, commercial, retail and residential concrete floors. The result of this system is higher quality and more durable polished concrete floors.

Diamond Surface, Inc. sets the standard for excellence in Heavy Highway Construction of diamond grinding, rumble stripping and concrete pavement restoration. Members of International Grooving and Grinding Association, Concrete paving Association and American Concrete Paving Association.

Sunbelt Rentals offers Concrete Floor Grinders for leveling, smoothing, and cleaning concrete surfaces. View our Concrete Floor Grinders today.

Apr 17, 2017· How to cut concrete pavement slab with a grinder without proper tool for cutting. ... This video is showing how to cut a concrete pavement slab by using a standard grinder.

Diamond grinding is a pavement preservation technique that corrects a variety of surface imperfections on both concrete and asphalt pavements. Most often utilized on concrete pavement, diamond grinding is typically performed in conjunction with other concrete pavement preservation (CPP) techniques such as road slab stabilization, full and ...

After grinding away the imperfections, it''s possible to produce a smooth, polished surface from a worn down slab of pavement or concrete. The Biggest Benefits of Concrete Diamond Grinding Smooth Surfaces. First of all, one of the more immediate benefits and results of grinding concrete .

Mar 29, 2012· RTI Research Project # is studying the longterm benefits of grooving pavement utilizing diamond grinding. ... a Concrete Slab for ... it might be the most important tool you ...

Nov 11, 2011· The results showed that diamond grinding is a viable method to improve surface characteristics of pervious concrete pavement and can restore permeability and rideability. SHOW CAPTION HIDE CAPTION ...

A handheld grinder could be one of the most versatile items in your tool chest. It''s a fast solution for smoothing out bumps and other irregularities in both horizontal and vertical concrete surfaces. You can also use it to remove graffiti and worn coatings or paint and to roughen up floor surfaces in preparation for coating application.

Deeper diamond grinding will expose the coarse aggregate in the concrete pavement. Softer coarse aggregates that are exposed may polish and result in lower skid numbers. The department developed special specifications for diamond grinding.

Effect of Diamond Grinding on Noise Characteristics 235 Effect of Diamond Grinding on Noise Characteristics of Concrete Pavements in California Shubham Rawool1 and Richard Stubstad2 ABSTRACT The construction of sound walls along highways has been the primary noise mitigation strategy in California and in many other western States.

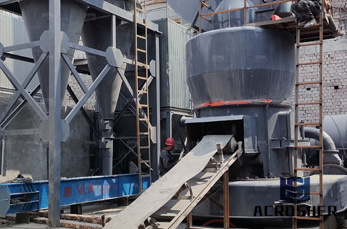

Diamond Grinding PRS offers high horsepower tier four engine diamond grinders as a maintenance solution for concrete and asphalt pavements. Corrective grinding provides a costeffective solution to eliminate unsafe surface bumps and create a smooth finish.

Grinding Wheels; CutOff Saw Blades; Bosch Tool Sale; Adhesive Sealants; Chain Hoists; Concrete / Pavement. Breaker Demolition; Concrete Mortar Mixers; Concrete / Grout; Concrete Calculator; Concrete Chemicals; Concrete Cutters; Concrete Nailers; Concrete Vibrators; Dust Extraction Bits; Forming Supplies; Masonry Tools; Sonotube Concrete ...

Publication Details Concrete Pavement Rehabilitation Guide for Diamond Grinding . Primary Topic: Pavement Rehabilitation. Description: Document briefly summarizes diamond grinding technique for rigid pavement restoration and discusses the concept, equipment, advantages, design considerations, construction, performance and document also provides an example guide specification.

Grooving has significantly reduced accidents on pavements that exhibit a low coefficient of friction or high accident rate. Signs installed on some sections of highway indicate that the highway surface has been grooved when it has, in fact, been cold milled by equipment using .

WhatsApp)

WhatsApp)