The comparison between vertical shaft furnace and rotary ...

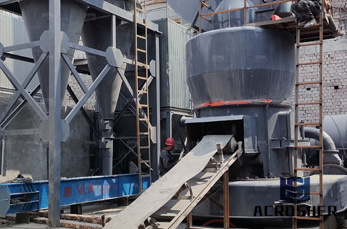

At present, the petroleum coke is mainly calcined by vertical shaft furnace or rotary kiln to meet the requirement of prebaked anode used for Aluminum reduction in China.

WhatsApp)

WhatsApp)

At present, the petroleum coke is mainly calcined by vertical shaft furnace or rotary kiln to meet the requirement of prebaked anode used for Aluminum reduction in China.

Once the calcined coke is discharged from the kiln, the coke is cooled in a rotary cooler. At the feed end of the cooler, water is sprayed on the calcined coke to cool the coke to acceptable temperatures. The water is evaporated in the process. Afterburner: The kiln exhaust gas is oxygen deficient and contains volatile matter released in the kiln.

upcoming coke calcination plant in saudiaraba BINQ Mining vertical shaft calciners suitable for petroleum coke calcination .. method for petroleum coke calcination, and the current production capacity is about 3,500Kt/a. . calcined petroleum coke plant in saudi

Calcined Petroleum Coke . Calcined Petroleum Coke is a critical ingredient in the production of aluminum. It is created by placing high quality raw "green" petroleum coke into rotary kilns, where it is heated to temperatures between 1200 to 1350 degrees C (2192 to 2460 F). Get Price; Petroleum Coke Calcined Petroleum Coke Manufacturer from ...

shaft kiln petro cokeCalciner Kiln Price. 2018 machine price of activated carbon calciner small,buy and sell used calciner and indirect fire dryers at,calc

Shaft Coke Petroleum Vertical EXART. Calcined petroleum coke (CPC) may be created using rotary kiln, hearth, or vertical shaft technology. Although different techniques may be used, the conversion from . Calcined Petroleum Coke Oxbow . Calcined Petroleum Coke is a critical ingredient in the production of aluminum. Chat Online »

Nov 30, 2017· A look at how Petroleum Coke is produced. A look at how Petroleum Coke is produced. Skip navigation Sign in. ... Calcined Petcoke producer .

Using A Lime Kiln For Calcining Petroleum Coke. Using A Lime Kiln For Calcining Petroleum Coke. May 02, 2013nbsp018332an advantage of the rotary kiln is that sulphur (s) from the fuel, and to a lesser extent from the limestone, can be expelled from the kiln in the kiln gases by a combination of controlling the temperature and the percentage of co in the calcining, low s lime can be ...

Particulate carbonaceous material, for example delayed petroleum coke, is calcined in an internallyfired vertical shaft kiln (10). A downwardlymoving bed of green coke is preheated in the top of the kiln by rising combustion gases, then heat soaked at calcining temperatures in the intermediate section of the kiln, and finally cooled by recycle gas moving upwardly from the lower part of the kiln.

Vertical shaft kiln (VSK) for Dolomite. Single shaft type, high performance and mix fire kiln system from kinc adds enormous advantages to lime | dolomite and economic way for lime and dolomite calcinations.

shaft kiln for petcoke calcination. Design Vertical Shaft Kiln Calcined Coke Shaft kiln for petcoke calcination design of the kiln burner is central to the success of the coal firing installation and indeed the kiln itself, petroleum coke is often coke is the best material for making carbon anodes for smelting of alumina to aluminum petroleum coke is usually ...

Blast Furnace and Process Description Chemical. Jul 12, 2019· Blast Furnace and Process Description: Iron blast furnace is a vertical shaft, which is used to melt the iron ore and to produce hot metal by heat exchange and chemical burden charge consisting of iron oxide, flux and coke and it provides through the throat from the top of the price

a new method of calcining coke in a vertical kiln in two zones to shorten the kiln residence time and to provide efficient heat transfer to the coke particles. green coke is dried, preheated and fed to a choking zone of a vertical klin for calcining in suspension with countercurrent flow of asceding flue gas, ten further calcined in a free all zone of the kiln by contact with ascending ...

Delayed petroleum coke is calcined in an internallyfired vertical shaft kiln. A downwardlymoving bed of green coke is preheated in the top of the kiln by rising combustion gases, then heat soaked at calcining temperatures in the intermediate section of the kiln, and finally cooled by recycle gas moving upwardly from the lower part of the kiln.

ZENIT. vertical shaft kiln for coke calcination Gasan Petroleum Coke Calciner heavy duty hand grinder machine bosch size 4 inch 3a Vertical shaft kiln. Vertical Compound Crusher ZME Vertical. The vertical compound crusher is widely fused calcium carbide, limestone, of the machine and are impacted and grinded under the effect of highspeed . coke .

offers 115 vertical shaft calciner products. About 68% of these are Cement Making Machinery, 0% are Industrial Furnace. A wide variety of vertical shaft calciner options are available to you, such as local service location, key selling points, and condition.

vertical shaft kiln for raw petroleum coke carexcellencebe. Vertical Shaft Calcination Process Description Documents Calcination The Green Petroleum Coke feed on top of the shaft kiln, the coke moves downward through the kiln, where due to the slow movement of the coke through the Calcining unit, all coke particles reach maximum Calcination ...

5 Modern plants use vibratory conveyors to transport the CPC on to conveyor belts leading to storage. Differences between shaft and rotary kiln calcining technologies

Calcined coke is the best material for making carbon anodes for smelting of alumina to aluminum. Petroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures, around 1200 to 1450 °C, to remove moisture, drive off volatile matters, increase the density of the coke, increase physical

Vertical Shaft Kiln For Coke Calcination. vertical shaft kiln for coke calcination biharurban. PetroleumCoke Calcining Technology American Chemical Society. When the hot (°C) calcined coke leaves the kiln, it is transferred to a rotary such calciners employ either batch or continuous vertical shaft kilns..

Particulate carbonaceous material, for example delayed petroleum coke, is calcined in an internallyfired vertical shaft kiln (10). A downwardlymoving bed of green coke is preheated in the top of the kiln by rising combustion gases, then heat soaked at calcining temperatures in the intermediate section of the kiln, and finally cooled by ...

vertical shaft calciner design petroleum coke. Aft Kilns Calcined Petroleum Coke In China. Coke Shaft Calciner Sizing mayukhportfolio. design machine calcined petroleum coke. design machine calcined petroleum coke YouTube . TECHNIP designed and executed 6 out of 15 Calciner . calcined petroleum coke vertical shaft kiln . Chat With Sales.

vertical shaft kiln for raw petroleum coke. vertical shaft kiln for coke calcination. Vertical Shaft Calcination Process Description Documents. Jul 31, 2017· Each shaft produces approx 120 kg/h CPC or 38 tph for all 32 shafts respectively 92 tons per day and kiln Calcination The Green Petroleum Coke feed on top of the shaft kiln, the coke moves downward through the kiln, where due to the slow ...

Calcined Petroleum Coke Introduction Production process Overview Rotary kiln calcined coke production Shaft kiln calcined coke production Green coke blending Conversion Factors 4. So urc ing fR awM t elp s Supply contracts Chinese coke Nontraditional anodegrade coke 4. get price

WhatsApp)

WhatsApp)